When it comes to solid-liquid separation, the choice between a Chamber Filter Press and a Membrane Filter Press can significantly impact your operational efficiency, costs, and compliance performance.

Each has clear advantages — the key is knowing which one fits your process, your priorities, and your industry best.

This guide highlights the strengths of each technology, provides a side-by-side comparison, and helps you identify which is better suited for your operation.

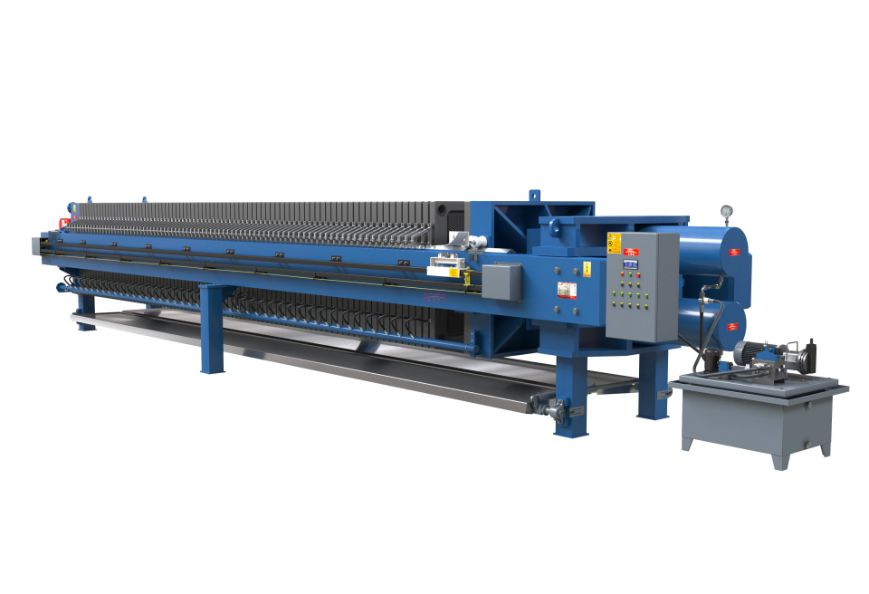

The Chamber Filter Press is a tried-and-true technology known for:

Lower upfront investment

Simple mechanical design

Easy maintenance and operation

Reliable performance in low-to-medium volume applications

Best for:

Plants with limited budgets

Processes with low solids concentration

Industries where cake dryness isn’t critical

Entry-level or first-time users of filter press systems

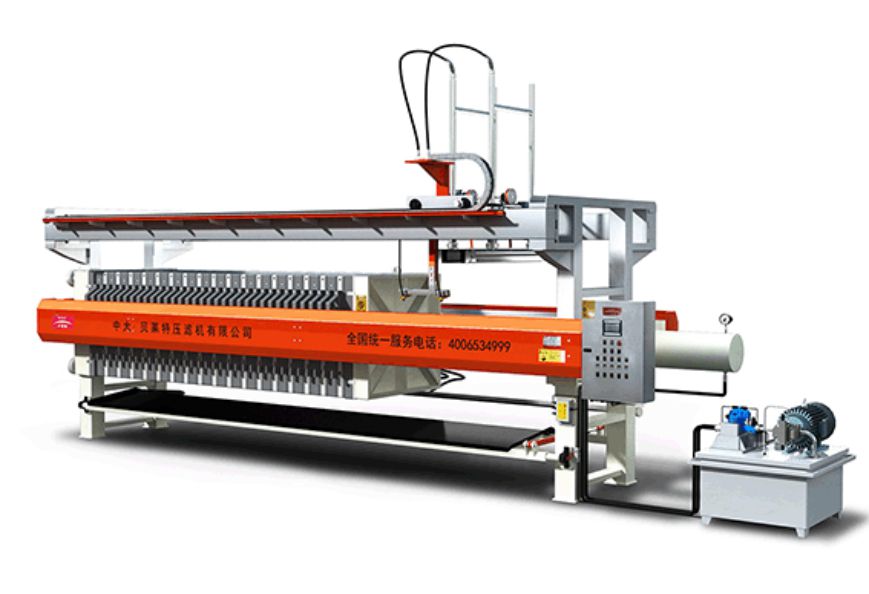

The Membrane Filter Press adds a second filtration step using inflatable membrane plates that apply additional pressure to the filter cake.

Lower final cake moisture (as low as 35–45%)

Faster cycle times

Reduced sludge disposal and drying costs

Better suited for automation and continuous operation

Improved cake uniformity and cleaner cake release

Best for:

Industries with high sludge disposal costs

Applications where dryness affects compliance or cost

Large-scale, automated operations

Businesses pursuing energy efficiency and sustainability goals

Side-by-Side Comparison

| Feature | Chamber Filter Press | Membrane Filter Press |

|---|

| Upfront Equipment Cost | Lower | Higher (20 |

| Cake Moisture Content | 55 | 35– |

| Filtration | Standard | Faster |

| Maintenance | Simple | Moderate |

| Automation | Limited | High ( |

| Operating Cost (Long | Moderate | Lower ( |

| Best Use Case | Budget-sensitive, | High |

Industry Fit: Who Should Use Which?

Chamber Filter Press Ideal For:

Small and medium-sized plants

Ceramics, textiles, light industrial wastewater

Operations with limited staff or low automation

Buyers focused on CapEx savings

Membrane Filter Press Ideal For:

Municipal and industrial wastewater

Mining and metallurgical operations

Chemical, pharma, and food industries

Companies aiming to reduce TCO and environmental impact

Quick Tip: If you’re paying high sludge transport or drying costs, membrane presses usually pay for themselves faster.

Ready to Find Your Best Fit?

Let our experts help you evaluate the ROI of each option based on your unique process needs.

[Request a Quote]