Maximize Dewatering Efficiency and Reduce Disposal Costs

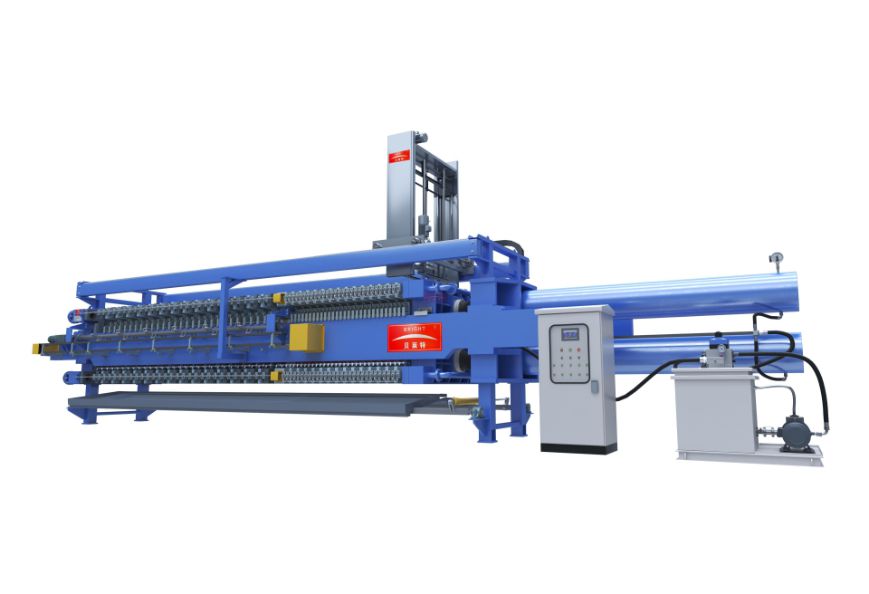

In sludge treatment and industrial filtration, efficiency means more than speed — it means lower moisture, less waste, and lower cost. The Membrane Filter Press is engineered to deliver all three.

Compared to conventional chamber presses, membrane presses significantly reduce the moisture content of filter cakes, directly lowering transport, drying, and disposal costs. Whether you're handling municipal sludge, industrial wastewater, or chemical slurry, switching to membrane technology can have a measurable impact on your bottom line.

Why Drier Cakes Matter

Moisture content in filter cakes plays a major role in downstream cost:

Higher disposal costs: More water means more weight — and higher hauling fees.

Increased drying energy: Thermal dryers must evaporate more water, increasing energy use.

Larger storage footprint: Wet cakes require more space and handling.

With a membrane filter press, you can reduce cake moisture to as low as 35–45%, compared to 55–65% for typical chamber filter presses.

Case Insight: A wastewater treatment plant cut sludge transport volume by 40% using a membrane filter press.

How It Works: Two-Stage Filtration

The membrane filter press uses a two-stage filtration cycle:

Primary Filtration: Solids are separated from liquid under pressure, forming a cake.

Membrane Squeezing: Flexible membrane plates inflate with air or water to compress the cake, squeezing out residual water.

This secondary compression:

Typical cycle times are 15–30% shorter than with chamber presses.

Real Savings: Total Cost Breakdown

Investing in a membrane filter press isn’t just a performance upgrade — it’s a long-term cost reduction strategy.

| Cost Area | Savings with Membrane Press |

|---|

| Sludge Disposal | ↓ Up to 40% in weight/volume |

| Energy for Drying | ↓ Less moisture, less energy needed |

| Labor | ↓ With auto-discharge and cloth washing |

| Filter Cloth Replacement | ↓ Cleaner cakes = longer cloth life |

Did you know? Every 10% drop in cake moisture can cut disposal costs by 15–20%.

Who Benefits Most

The membrane filter press is ideal for processes where disposal or drying costs are high:

Municipal wastewater treatment

Mining & mineral processing

Chemical & pharmaceutical production

Food and beverage waste handling

Textile and dye wastewater

Support for Environmental Compliance

In many countries, landfill and discharge regulations are getting stricter. The membrane press helps:

Meet sludge dryness requirements for landfill

Reduce emissions from sludge incineration

Align with corporate ESG or sustainability initiatives

Less moisture. Less waste. Smaller footprint.

Conclusion: Better Performance, Lower Operating Costs

If you're still using a traditional chamber filter press, it's time to consider the upgrade.

With a Membrane Filter Press, you benefit from:

Ready to see what a membrane filter press can do for your process?